Demineralization Plants (DM Plants)

Demineralization Plants (DM Plants) are used in the Demineralisation process where the minerals and salts are removed from the water. Demineralization is done with the help of the Ion exchange process.

Demineralized od water means removing all the dissolved mineral from the water completely, so providing almost zero dissolved mineral. This can be done with the help of the following processes

- Deionization by Ion Exchange Technique

- Distillation by Heat

- RO Membrane filtration or Nanofiltration

- Electrodialysis

DM Water

The water which has its minerals removed is also known as Demineralized Water. Mineral ions contain cations Sodium, Magnesium, Calcium, Iron, Copper, and other heavy metals It also contains anions such as Chloride, Sulfate, Nitrate, etc. These are the common ions which normally present in the water.

At Soni Enterprises, we manufacture a wide range of Demineralization Plants (DM Plants) as per the requirement of clients. We are the leading DM Plant supplier in India and Delhi NCR. Demineralized Water plant (DM Plant) used in various industries in India for different industrial process water applications.

These optimum designed plants provide various benefits including water conservation and saving cost.

De-mineralization Process

In the Deionization process a specially-manufactured ion exchange resins it used which provides an ion exchange site for the replacement of the mineral salts in Water by forming H+ and OH- ions. Since water mainly contains water impurities which are dissolved salts, deionization produces provides very high purity water.

This water is generally similar to distilled water but this process is very quick and without any much energy usage. So this provides demineralize water at very low lost

De-mineralization technology is widely used in almost the industries where deionized water is used in any form. Because this is a proven process for the treatment of Water and making is mineral-free. A DM Water uses the process of and principles of ion exchange, Degasification, and polishing. We have described these processes in short for your understanding.

Demineralized Water is used in many applications and in various industries e.g. Pharma, Automobiles, Food Processing, Water Treatment, Power, Electroplating, and many more.

Principle Of DM Plants

In the Demineralization Plants (DM Plants), inlet water is entered through tanks having ion exchange resins beds.

In this the cations get exchanged with hydrogen ions in the first bed, the anions are exchanged with hydroxyl ions, in the second one.

In typical water following ions are widely found :

Cations : Calcium (Ca2+), Magnesium (Mg2+), Potassium (K+), Sodium (Na+)

Anions: Chloride ( Cl-), Carbonate (CO32-), Bicarbonate (HCO3-), Nitrate (NO3-)

Types Of DM Plants

The DM Plants are available in various sizes, types, and uses different media for ion exchange. DM plants can be manually operated or fully Automatic. These. Demineralized Water plants come ready to install & are available as standard models or can be build custom as per the client requirements

Normally there are two types of DM plants used widely.

- Two Bed DM Plant

- Mixed Bed DM Plant

Types Of DM Plants

Two Bed Demineralization Water Plant (DM Plants)

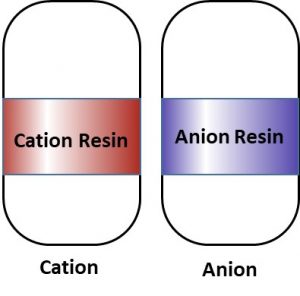

In the two-bed Demineralization Plants (DM Plants), there are two vessels used for the treatment. One vessel contains the cation exchange resin om the form of hydrogen ion (H+) and another contains the anion resin in the form of hydroxyl ion (OH-).

The two-bed demineralization water plant has a pressure vessel which can be an MS/FRP or SS vessels. The plant can be provided with rubber lining depending on the MOC. The vessels are connected in series and have ion exchange resins.

At first, the water flows from the cation column where all the cation exchanges with hydrogen ions. For example, the sodium ion Na+ changed with H+ ion. After that, the water goes into the anion bed, and here the hydroxyl ion-exchanged with the negatively charged ions.

The H+ ion from the cation bed and OH- ion from the anion column mix with each other and form the H2O and hence all then the resin can be removed while the regeneration of the resin and the beds will be ready for reuse.

Mixed Bed Demineralization Water Plant (DM Plants)

In the mixed bed both the resin available for treatment and hence the length of the vessel is more as compared to two-bed Demineralization Water Plant. Hence the quality of water resulted from the mixed-bed deionizer is higher than that of water produced by a two-bed demineralization Water Plant.

Because of this type of design, the mixed bed DM plants are more sensitives and delicate to the impurities present in the water. Mix bed DM plant does the polishing of the water and hence provide completely pure water without negligible minerals.

This is the reason why a mixed bed is preferred over two bed DM Plant and reverse osmosis plants where the water purity requirement is very high.

Other Parts of DM Plant

DM Plant De-Gasifiers

Degasser or de-gasifier is an integral part of the demineralization plant because it removes the carbon dioxide gas generated by the dissociation of carbonic acid at the cation outlet water.

Hence the de-gasifier is generally placed between cation and anion exchanges

This results in cost savings because it reduces chemical consumption. A Standard de-gasifier consists of a tower in MS rubber lined or FRP construction with a pump and blower.

Condensate Polishing Unit

CPU (Condensate Polishing Unit) Condensate polishing typically involves ion

exchange technology for the removal of trace dissolved minerals and suspended matter. During the process of steam generation in power plants, the steam cools and condensate forms.

We provide a high quality of condensate polishing ion exchange resins excels in capturing corrosion products in the condensate stream. This polishing typically involves ion exchange technology for the removal of trace dissolved minerals and suspended matter.

Portable DM Plants

Normally the DM plants are big in size are used for the high amount of water treatment, but there are portable or mini DM plants available with us which can be used for the small amounts of water used in various industries or small or medium scale businesses.

Operation of DM Plants

The DM plants can be operated manually by the water treatment operator or can be made fully automatic as per the requirement of clients. The same can be done with the help of PLC Controlled systems wherein normal operation operator involvement is negligible.

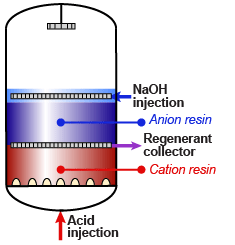

Regeneration of DM Plants

The DM plants require regeneration of resins on a regular basis. This mainly depends on the capacity and amount of water treated by the Demineralization Water Plant. Normally a regeneration cycle takes just 30-60 minutes.

The DM Plant uses the acid and base for regeneration and hence the outlet water neutralizes itself. So the load of the water treatment plant can be reduced by doing regeneration in an effective manner.

Benefits Of DM Plants

- Demineralization water plants are useful in the removal of salt and other harmful contaminants that are dissolved in water and provide almost negligible mineral water.

- The water generated by the demineralization is far better -distilled water.

- DM water plant comes in a variety of sizes and specifications so can be used in any industry or small scale businesses.

- Using a demineralized mineral water plant removes all the impurities from the water including heavy metals.

- Most of the DM water plants do not require much storage space and provide continuous water flow.

- The cost of water treatment is far less than distilled water.

Benefits Of DM Plants

- Battery Water Plants

- Boilers feed Water in Industries

- Textiles and Laundries.

- Pharmaceuticals Plant

- Chemicals Plants

- Breweries and Distillers

- Hotels and Swimming pools,

- Packaging Water Plants

- Hospitals,

- AutomobileIndustries,

- Pesticides and Fertilizers Industries and many more

About Soni Enterprises

Advantages Of Soni Enterprises

At Soni Enterprises we understand the client requirement and provide cost-effective products at the best price and quality. We have a dedicated service team that can provide various kinds of installation, AMC, operations, etc. as per the requirements.

Some of the key benefits of Soni Enterprises are :

- Quality product with better efficiency

- Low energy consumption

- DM Water Plant at the best price

- Dedicated Teams

- Quality Check at Various Levels

- Low maintenance

- Auto Operation

- Low Chemical Consumption

- Quick Installation

- Compact and Portable DM Plants

Our DM Water Products

- Mixed bed DM Plant in Different Sizes

- Two bed DM plant in Different Sizes

- DM plant in MS

- DM Plant in FRP

- Compact and Portable DM Plants

- Fully DM Plants

Check out our RO Plants also which are compatible with DM plant and can reduce down a load of DM plant if installed before DM Plant.

You can also check out UV sterilization machine for sterilization of your tools, documents, parts and other products.